Building Mushroom Boat 2

Mushroom Boat 2 weighs 107 lbs and is sealed with shellac and beeswax. It’s grown from the mycelium of a single wild Ganoderma polychromum polypore mushroom I harvested near my studio and cloned. The mycelium was propagated on 550 lbs of a hemp hurd substrate packed inside a custom two-part fiberglass form. The boat grew for 7 weeks and was dried over about 4 months..

Construction of Mushroom Boat 2 began in December of 2024. My cousin Laza and I engineered Mushroom Boat 2 with the computer-aided design (CAD) modeling plugin Shape3d, and applied the data gathered while testing Mushroom Boat 1 to fully optimize the design for an ocean kayak made of mycelium.

We added a deep keel to the original design to improve tracking and control over directionality. The first boat, with its rudderless flat bottom, was difficult to steer. Even in the calm marina at Long Beach, it spun like a paper plate in the wind. Thanks to Laza, we borrowed a feature from the “hot curl” surfboard and created a V-shaped keel that would keep the boat hydrodynamic and moving straight in turbulent open water.

We also used a Styrofoam “plug,” a dummy kayak around which we constructed the fiberglass shell for the second boat, which was approximately 50% larger by volume but 2.5 feet (0.76 meters) shorter than the fishing kayak used to build Mushroom Boat 1, making its final length approximately 12 feet (3.7 meters). This means it was also shorter than the average length of ocean-touring kayaks (which measure between 14 feet (4.3 meters) and 25 feet (7.6 meters), but the challenges and costs of engineering a 20-foot (6.1-meter) boat from mycelium outweighed the control afforded a more manageable length. I also worried that a longer boat would be more likely to break at sea (consider how easy it is to break a long branch versus a short branch). With further research and testing, I believe one could engineer a stronger, lighter, longer, and more hydrodynamic boat, but with the resources and information that were available to us, I believe we made the right assessment in limiting the length of Mushroom Boat 2.

To design a kayak specifically for mycelium, you have to account for the 18%–20% of volume lost to shrinkage. In the documentation, I look squished and uncomfortable paddling in my first mushroom boat because the fiberglass form was not designed for mycelium. Mushroom Boat 1 was operable, but it felt like wearing a pair of shoes that were one size too small. Narrow shrunken, it was also less stable in the water compared to its model. Knowing this, we made the foam plug for Mushroom Boat 2 that was 20% larger than the boat’s projected final dimensions. (Note: A 20% reduction in volume due to shrinkage doesn’t mean the final product will be 20% shorter. Since shrinkage affects all dimensions (length, width, and height), the loss in length alone might be closer to 10%.)

The keel on Mushroom Boat 2 provided rigidity, in addition to improved tracking, because it created an “I-beam effect” and acted as a spine for the boat. Mushroom Boat 1, by comparison, bent upwards at both ends when on the water and was unable to fully support my weight during use. Mushroom Boat 2 is also more rigid simply because it was built with more material. Mushroom Boat 1 is 4 to 6 inches (10 to 15.2-centimeters) deep along most of its hull, which proved to be too flexible under my weight. Mushroom Boat 2, though shorter, has a depth between 6 and 8 inches (15.2 and 20.3 centimeters) throughout, which offers more stability and control. Even after paddling across the ocean for twelve hours, Mushroom Boat 2 neither warped nor bent. In general, too much rigidity is better than not enough, but it did prove to be helpful that Mushroom Boat 2 possessed a little give, which allowed it to absorb a great deal of shock and force on the water. While paddling, I could feel small amounts of flex move throughout the boat when I hit the ocean swells. I believe this made for a smoother ride than something as inflexible as stone.

Fulcrum Arts raised enough money to rent us a production space at a surfboard factory in Ventura for two weeks to shape our plug. With our 3D renderings and a pickup truck full of salvaged Styrofoam blocks (donated by Meghan Gordon, the director of artist operations at OCHI Gallery in Los Angeles), a DIY hot wire cutter, epoxy, and a large haul of UV-activated surfboard fiberglass resin, we got to work. Laza and I spent long days in this windowless facility, building the two-part fiberglass form. We had just enough material to amalgamate the Styrofoam blocks with epoxy, expanding foam, and chopsticks. We coated the plug in a thin layer of epoxy before applying the fiberglass to prevent the resins we would be using from disintegrating the plug’s Styrofoam, and we rubbed a thick layer of car wax on the epoxy as a release to prevent the epoxy from permanently bonding to the resin. We also attached strips of plastic laminate measuring 6 inches (15.2 centimeters) wide to the lower lip of the plug with hot glue and caulk to create a “seam” that connected the top and bottom halves of the fiberglass shell. The whole thing was too large to place inside the factory’s UV bed or carry outside and into the sun while the resin was wet, so we added small amounts of catalyst to accelerate the resin’s curing time. It goes without saying, but always wear appropriate respiratory masks and ensure proper ventilation when doing this kind of work.

After applying a wet coat of resin to the top half of the plug, we laid approximately eight layers of fiberglass (cut to the length of the plug) over its surface and let it cure. We then removed the shims, waxed the epoxy and fiberglass seam, and repeated the same process to fabricate the other half of the form. We cut the irregular edges of fiberglass along the seam with a jigsaw and sanded the surface smooth. This stage of the process was highly technical, and I could not have done it by myself, but the grant money raised by Fulcrum Arts made it possible to hire my cousin and compensate him adequately for his skills and labor. I recommend building relationships with board-shapers, boatbuilders, or autobody repair people who have the technical skills and willingness to collaborate with you if you’re in a similar position.

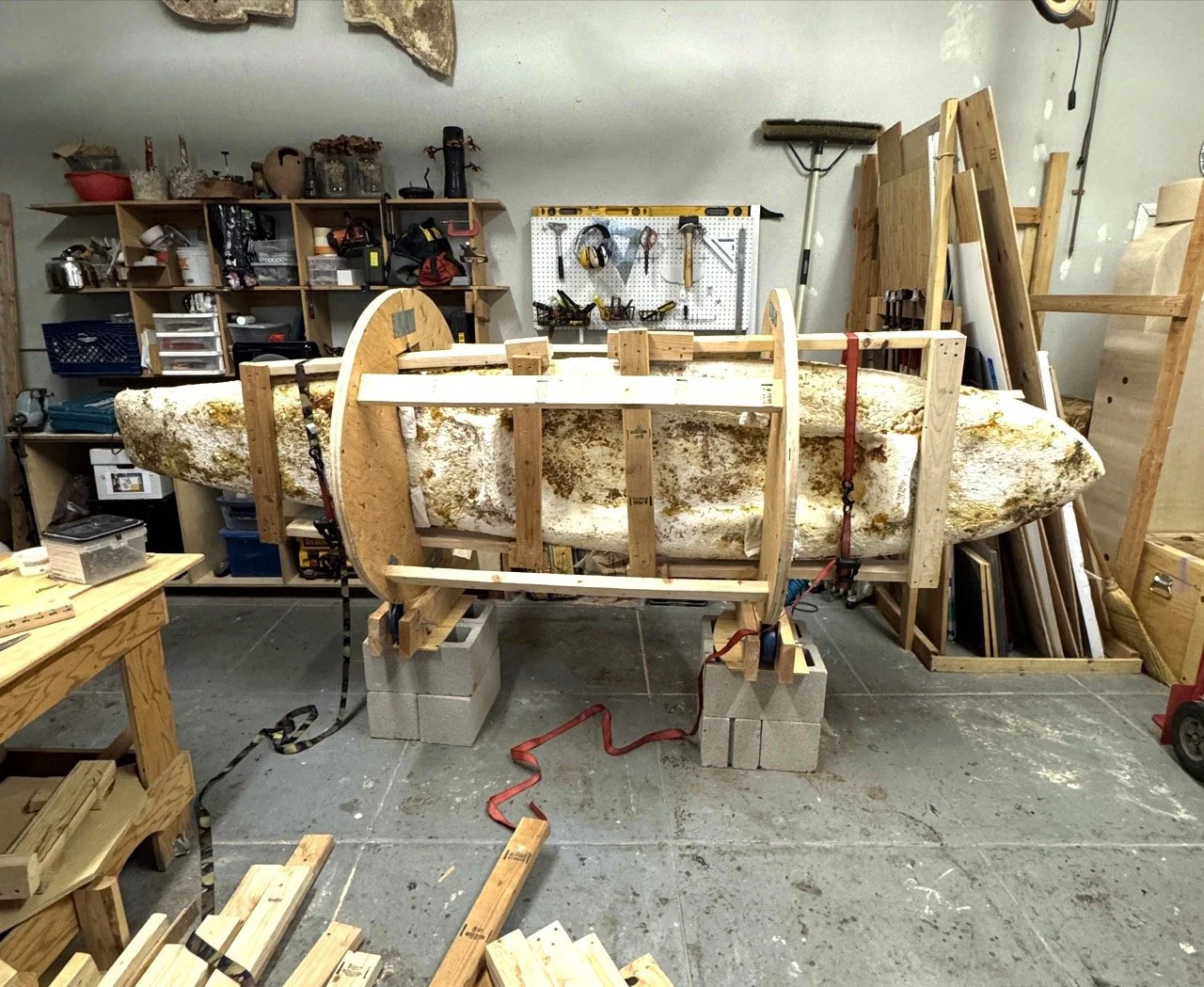

Laza helped me design a circular plywood brace system that functioned like a giant rotisserie, which allowed Mushroom Boat 2 to be rotated on casters during incubation, late-stage growth, and drying. Mushroom Boat 1, which was nearly 200 pounds (90.7 kilograms) lighter, had been challenging to handle, and like Mushroom Boat 1, Mushroom Boat 2 needed to be periodically flipped to ensure even growth and drying. With the brace system I was able to access both sides of Mushroom Boat 2 without volunteers or difficulty.

To build the brace, we cut plywood circles 4 feet (1.2 meters) in diameter. Each circle was made from two sheets of plywood laminated together to create a thickness measuring 1.5 inches (3.8-centimeters), which was strong enough to support the boat’s 600 pounds (272.2 kilograms). Cross sections for the fiberglass hull were cut into the plywood circles, with careful attention to aligning the boat’s central axis of weight so that rotations remained balanced. Two circular braces, spaced about 4 feet (1.2 meters) apart, distributed the load evenly during incubation and drying. The braces sat above cinder blocks and were mounted on paired sets of casters, one set at each end, and each circle was cut in half to allow the boat to be set inside, then reinforced with lumber two-by-fours for strength.

Overall the improvements from Mushroom Boat 1 to Mushroom Boat 2 exceeded my expectations. With more resources and support available for this second attempt, production went very well, and only minor adjustments were made to how Mushroom Boat 2 was inoculated, packed, incubated, and dried. It is difficult to imagine we could have done more with the resources and information available to us at this stage.

Mushroom Boat 2 weighs 107 lbs and is sealed with shellac and beeswax. It’s grown from wild Ganoderma polychromum mycelium I harvested near my studio, propagated on 520+ lbs of a hemp hurd substrate packed inside a fiberglass mold. It grew over 7 weeks and dried for 3+ months. Growing the mycelium between layers of cotton textiles added enough strength to create a monolithic composite structure capable of sea travel.

My paddle is made from spruce and persimmon wood, stained with jumbo gym (Gymnopilus ventricosus) mushrooms cultivated in my lab.

The crossing: I successfully paddled across the Catalina Channel in Mushroom Boat 2 on August 5, 2025. A 26.5 mile journey over 12 hours. Two Harbors -> Cabrillo Marina. You can read more about my journey in this Guardian feature by Lisa Kwon.

A brief timeline of my crossing:

Monday Aug 4: Captain Andrei Nemoi sails our crew to Catalina Island with the mushroom boat. We eat dinner and sleep on his boat.

Aug 5, 6am: Paddling begins

Miles 3-9: Rough cross swells and currents. Losing sight of land. Moving slowly. I become sick and begin hallucinating shapes in the water. I begin doubting the journey. Jordan Freeman follows in dinghy for videography (credit to Jordan for the still in the image attached)

Miles 9-17: Swells even out and conditions improve. I break my “carry everything” rule to request an earbud from the crew in order to listen to music to regain sanity. I do not regret this decision. Fin whales appear, following me for many miles. Repeatedly breaching a few feet from my boat, swimming directly behind me like a curious dog. Crossing the commercial shipping lane goes smoothly. At mile 17 I eat the lunch packed in my dry bag, a peanut butter sandwich on toasted bread with honey and Szechuan chili flakes.

Miles 17-24: Turbulent refractory waves and afternoon winds approaching the Cabrillo lighthouse. This section is difficult but smoother than expected.

Miles 24-26.5: The longest shortest distance. Splashy choppy water against 14 knot wind through Marina. The most strenuous stretch of the journey.

Thanks to: Patrick J. Reed, Robert Novak, Jordan Freeman, cousin Laza Panich, Christopher Wormald, James Anderson (paddle fabricator), Phil Ross & Open Fung, Julie Beeler, and Ochi Gallery for their support with this project

Fulcrum Arts’ programming is made possible with the generous support of the Perenchio Foundation, the National Endowment for the Arts, J. Paul Getty Trust, the Andy Warhol Foundation for the Visual Arts, California Arts Council, Los Angeles County Department of Arts and Culture, the Wilhelm Family Foundation, and the Pasadena Arts and Culture Commission and the City of Pasadena Cultural Affairs Division.

Updates on our successful mushroom boat Catalina Channel crossing coming soon. Still by Jordan Freeman